Primary Reverse Osmosis Pure Water Equipment

Product Description

Product Description

Chemical Pure Water Equipment

Ultra-pure water equipment adopts pretreatment, reverse osmosis technology, ultra-purification treatment and post-treatment methods to almost completely remove the conductive medium in the water, and remove the non-dissociated colloidal substances, gases and organic substances in the water to a very low level. Water Treatment equipment works fabulously. Pure water equipment uses mainly reverse osmosis membrane technology.

Industrial Pure Water Equipment working principle is to apply a certain pressure to the water to make the water molecules and ionic mineral elements pass through the reverse osmosis membrane, and most of the inorganic salts (including heavy metals), organic matter, bacteria and viruses dissolved in the water are impenetrable. Pass the reverse osmosis membrane, so that the pure water that has been permeated and the concentrated water that cannot be permeated are strictly separated; the pore size on the reverse osmosis membrane is only 0.0001 microns, while the diameter of the virus is generally 0.02-0.4 microns, and the diameter of ordinary bacteria is 0.4 -1 micron.

(1) Purpose of ultrapure water equipment:

1. Production and cleaning of ultrapure materials and ultrapure reagents. 2. Production and cleaning of electronic products. 3. Production of battery products. 4. Production and cleaning of semiconductor products. 5. Production and cleaning of circuit boards. 6. Production of other high-tech fine products.

(2) Purpose of pure water equipment:

1. Chemical water treatment in power plants 2. Ultra-pure water in the electronics, semiconductor, and precision machinery industries 3. Preparation of food, beverages, and drinking water 4. Small pure water stations, drinking pure water for groups 5. Fine chemicals, water for sophisticated subjects 6. Preparation of high-purity water required by other industries 7. Process water for pharmaceutical industry 8. Desalination of sea water and brackish water

1. Water quality of ultrapure water: Resistivity>15MΩ.cm Ultrapure water quality is divided into five industry standards, namely 18MΩ.cm, 15MΩ.cm, 10MΩ.cm, 2MΩ.cm, 0.5MΩ.cm. Distinguish different water quality.

2. Pure water: industrial pure water and drinking pure water, industrial pure water: at 25 degrees Celsius, 1. Ordinary pure water: EC=1~10us/cm; 2. High purity water: EC=0.1~1.0us/cm; 3. Ultrapure water: EC=0.1~0.055; drinking pure water: EC=1~10 us/cm (national standard).

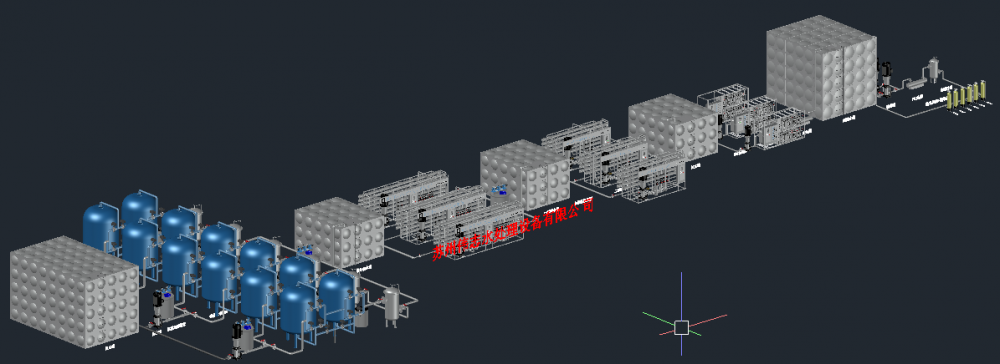

Three, the process flow used between various equipment is different

(1) The technological process of ultrapure water equipment is:

1. Pretreatment system → reverse osmosis system → intermediate water tank → coarse mixed bed → fine mixed bed → pure water tank → pure water pump → ultraviolet sterilizer → polished mixed bed → precision filter → water object (≥18MΩ.CM) (traditional Craft).

2. Pretreatment → reverse osmosis → intermediate water tank → water pump → EDI device → purified water tank → pure water pump → ultraviolet sterilizer → polished mixed bed → 0.2 or 0.5 μm precision filter → water object (≥18MΩ.CM) (the latest technology) .

3. Pretreatment→first-stage reverse osmosis→dosing machine (PH adjustment)→intermediate water tank→second-stage reverse osmosis (positive charge reverse osmosis membrane)→pure water tank→pure water pump→EDI device→ultraviolet sterilizer→0.2 or 0.5μm precision filter → water object (≥17MΩ.CM) (the latest technology).

4. Pretreatment → reverse osmosis → intermediate water tank → water pump → EDI device → pure water tank → pure water pump → ultraviolet sterilizer → 0.2 or 0.5 μm precision filter → water object (≥15MΩ.CM) (the latest technology).

5. Pretreatment system → reverse osmosis system → intermediate water tank → pure water pump → coarse mixed bed → fine mixed bed → ultraviolet sterilizer → precision filter → water object (≥15MΩ.CM) (traditional process).

(2) The technological process of pure water equipment is:

1. Adopt ion exchange method

Raw water → raw water pressure pump → multi-media filter → activated carbon filter → water softener → precision filter → cation resin filter bed → anion resin filter bed → anion and yang resin mixed bed → microporous filter → water point

2. Adopt two-stage reverse osmosis method

Raw water → raw water pressure pump → multi-media filter → activated carbon filter → water softener → precision filter → first-stage reverse osmosis → PH adjustment → intermediate water tank → second-stage reverse osmosis (the surface of the reverse osmosis membrane is positively charged) → Purified water tank → pure water pump → microporous filter → water point

3. Adopt EDI method

Raw water → raw water pressure pump → multi-media filter → activated carbon filter → water softener → precision filter → primary reverse osmosis machine → intermediate water tank → intermediate water pump → EDI system → microporous filter → water point

Product Categories : Pure Water Equipment > First-level Reverse Osmosis Pure Water Equipment